Technology With Purpose

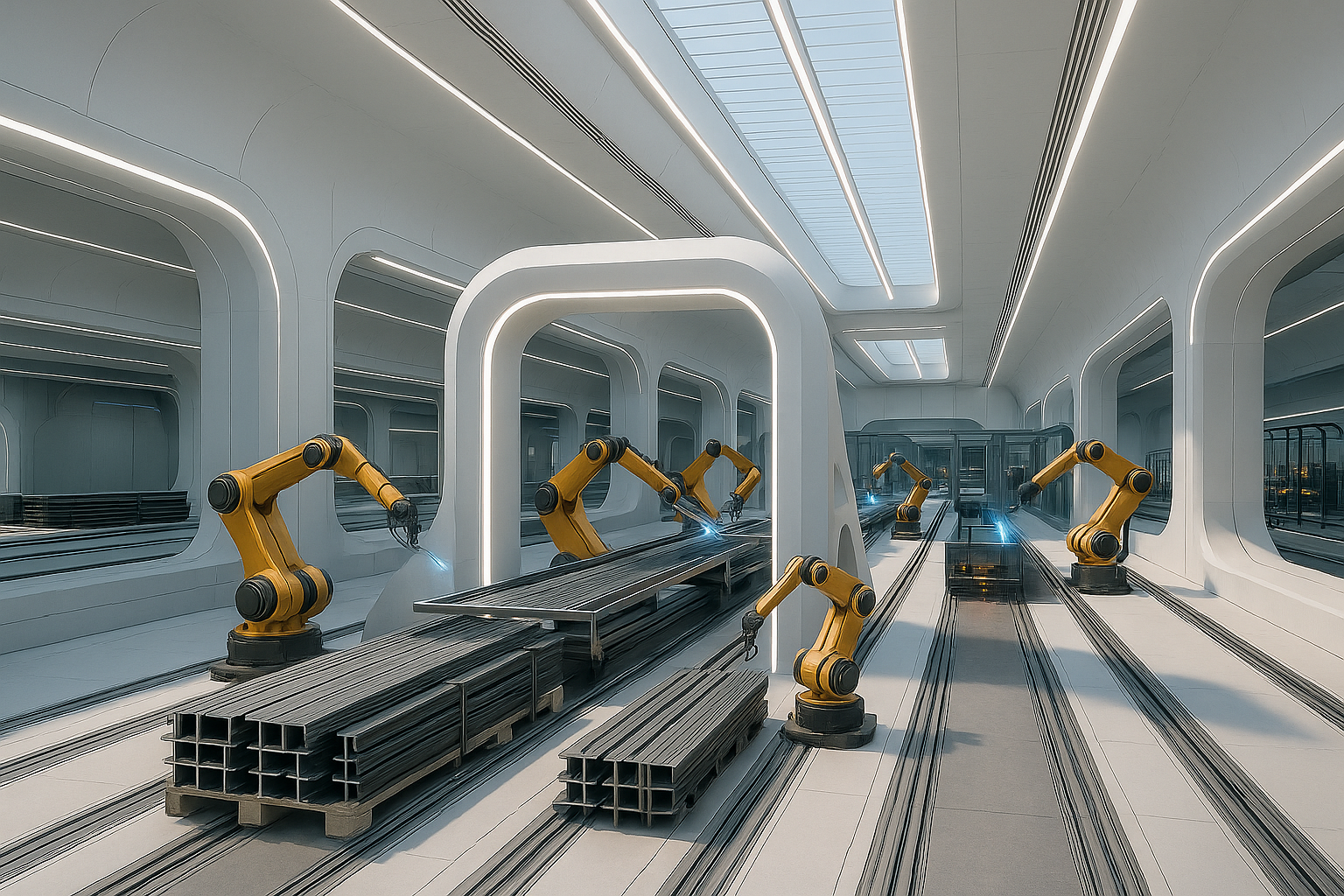

GloGreen integrates advanced manufacturing, materials systems, automation, and digital workflows to support local infrastructure production.

Our Innovation Stack

These capabilities are being developed to enhance delivery timelines and service life through automation-driven consistency, subject to project conditions and validation.

Precision Composite Fabrication

Advanced material systems engineered for durability and performance

Automated Manufacturing

Scalable production systems for rapid, consistent output

Coordinated Supply Chain Systems

Integrated logistics for efficient material flow

AI-Assisted Planning

Digital optimization for project planning and execution

Integrated Finance Workflows

Streamlined economic models for project delivery

Design Freedom + Regional Identity

GloGreen campuses are engineered to enable flexibility while respecting context

- •Enable custom architecture at manufacturing scale

- •Reflect regional identity

- •Adapt to climatic and cultural context

Residential Architecture

Public Services

Community Spaces

Ultra High Performance Nano Composite (UHPNC) Platform

GloGreen collaborates with Esurfact to advance UHPNC—a materials and automated manufacturing platform that aligns composite science with factory-based production, robotics, precision molds, digital QA/QC, and controlled curing environments.

This factory model enables repeatability, automation-driven consistency, and reduced lifecycle maintenance instead of boutique specialty concrete approaches.

UHPNC systems are engineered to deliver blast-resilient, durable structural performance designed to:

Improve Durability

Reduce Corrosion Pathways

Extend Service Life

Reduce Lifecycle Maintenance

These materials are being advanced through evaluation pathways including AREMA and ICC-ES (research phase), with testing and certification coordinated through appropriate bodies.

Deployment Models

GloGreen campuses can be positioned for:

Rapid Deployment Model

Permanent Infrastructure Model

Scaled Research Model

Permanent Infrastructure Production

Long-term manufacturing facilities for ongoing community needs

Resilience Hubs

Strategic positioning for rapid response capability

Disaster-Response Manufacturing

Emergency deployment for critical recovery operations

Coastal & Environmental Protection

Components for climate-resilient infrastructure

Public Development Programs

Support for government-led building initiatives

Explore Partnership Opportunities

Learn how GloGreen's technology can support your infrastructure goals.